This article is a joint article between the Associated Press and Grist.

Jeremy Ford hates wasting water.

As misty rain drifted across the fields of Homestead, Florida, Ford lamented how expensive it is to run a fossil-fuel-fueled irrigation system on his five-acre farm, and how bad it is for the planet.

Earlier this month, Ford installed an automated underground system that uses solar pumps to periodically saturate the roots of crops, estimating that it has saved “thousands of gallons of water.” Although the upfront costs may be higher, he sees these climate-friendly investments as a necessary expense and cheaper than adding two people to his workforce.

“It’s much more efficient,” Ford said. “We were trying to figure out, ‘What should we do?’ “With minimal additional labor.”

Ayurella Horn-Müller / Grist

More and more companies are introducing automation into agriculture. This could alleviate the sector’s deepening labor shortage, help farmers manage costs and protect workers from heat waves. Automation can also improve yields by increasing the accuracy of planting, harvesting and farm management, potentially alleviating the challenges of growing food in an increasingly warm world.

But many small farmers and producers across the country are not convinced. The barrier to adoption goes beyond the steep price tag and the question of whether the tool can perform nearly the same tasks as the workers it replaces. Some of those same workers wonder what this trend means for them and whether machines will lead to exploitation.

On some farms, driverless tractors grow corn, soybeans, lettuce and more. Although such equipment can be expensive and requires learning new tools, row crops are fairly easy to automate. It will be much more difficult to harvest small, uneven and easily damaged fruits such as blackberries, or large citrus fruits that require some strength and dexterity to pull off the tree.

That doesn’t deter scientists like Xin Zhang, a biological and agricultural engineer at Mississippi State University. She is working with a team at the Georgia Institute of Technology to apply some of the automation techniques used by surgeons and the object recognition capabilities of advanced cameras and computers to create a berry-picking robotic arm that can pick fruit without creating goo. wants to create. , purple mess.

Scientists have worked with farmers for field trials, but Zhang isn’t sure when the machine will be ready for consumers. Although robotic harvesting is not widespread, some products have hit the market. orchards in washington to Produce Farms in Florida.

“I think this is the future,” Jang said.

Is USDA’s spending on ‘climate-smart’ agriculture actually helping the climate?

But where she sees possibilities, others see problems.

Frank James, executive director of Dakota Rural Action, a grassroots agricultural organization, grew up on a cattle and crop farm in northeastern South Dakota. His family once employed a few farm hands, but had to reduce their workforce, in part due to labor shortages. Now most of the work is done by his brother and sister-in-law, with his 80-year-old father also joining in occasionally.

They swear by Tractor Autosteer, an automated system that communicates with satellites to keep the machines on track. However, their inability to identify moisture levels in the field can hamstring tools or clog tractors, and they require human supervision to operate properly. This technology also complicates maintenance. For this reason, he suspects that automation will be the “absolute” future of agricultural operations.

“Building relationships with the land, the animals and the places that produce them. And we’re moving away from that,” James said.

Charlie Neibergall/AP Photo

Tim Bucher grew up on a farm in Northern California and has been working in agriculture since he was 16. Dealing with weather issues like drought has always been a fact of life for him, but temperatures regularly reach triple digits and blankets of smoke wreak havoc on entire vineyards.

Faced with a combination of labor issues and the devastation of climate change, he combined his agricultural experience with his Silicon Valley engineering and startup background to found Agtonomy in 2021. Agtonomy works with equipment manufacturers such as Doosan Bobcat to create automated tractors and other implements.

Bucher said that since the pilot program began in 2022, the company has had a “flood” of customers, mainly vineyard and orchard growers in California and Washington.

The people who feed America are starving.

Supporters of the sector say farmers, who are often skeptical of new technology, will consider automation if it can make their businesses more profitable and make their lives easier. Will Brigham, a dairy and maple farmer in Vermont, sees these tools as a solution to the country’s agricultural workforce shortage.

“Many farmers are struggling with their work,” he said, adding that “competition is fierce” for jobs that are “unaffected by the weather.”

Brigham’s family farm has been using Farmblox, an AI-based farm monitoring and management system, since 2021 to help solve problems such as leaks in tubing used in maple production. Six months ago, he joined the company as a senior sales engineer to help other farmers embrace technologies like this.

Charlie Neibergall/AP Photo

Detasseling corn was a rite of passage in the Midwest. The teens wade through the sea of corn, removing the tassels (the part that looks like a yellow feather duster at the top of each stalk) to prevent unwanted pollination.

Extreme heat, drought and heavy rain have made labor-intensive work more difficult. And now it’s being done more often by migrant farm workers, who sometimes work 20 hours a day to keep up. That’s why Jason Cope, co-founder of farm technology company PowerPollen, believes it’s essential to mechanize tough tasks like tassel removal. His team created a tool that allows tractors to be used to collect pollen from male plants without removing the tassels. You can then save them for future crops.

“We can explain climate change by perfectly timing the pollen transfer,” he said. “And it requires a lot of labor that’s hard to take out of the equation.”

Charlie Neibergall/AP Photo

PowerPollen intern Evan Mark prepares a pollen spreader near Ames, Iowa, Thursday, August 22, 2024. Charlie Neibergall/AP Photo

Charlie Neibergall/AP Photo

The machine harvests corn pollen and collects it in containers. Charlie Neibergall/AP Photo

Charlie Neibergall/AP Photo

Erik Nicholson, who previously worked as a farm labor organizer and now runs Semillero de Ideas, a nonprofit focused on agricultural workers and technology, said farm workers are concerned they will lose their jobs to automation. Some people have expressed concerns about safety when working with self-driving machines, but have been hesitant to raise concerns for fear of losing their jobs. He’d like to see the companies that make these machines and the farmers who use them put people first.

Luis Jimenez, a dairy farm worker in New York, agrees. He described one farm that uses technology to monitor cattle for disease. These types of tools can help identify infections faster than dairy farmers or veterinarians.

They also help workers find out how the cows are doing, Jimenez said in Spanish. But they could reduce the number of people needed on farms and put additional pressure on workers who remain, he said. This pressure is compounded by increasingly automated technologies, such as video cameras used to monitor worker productivity.

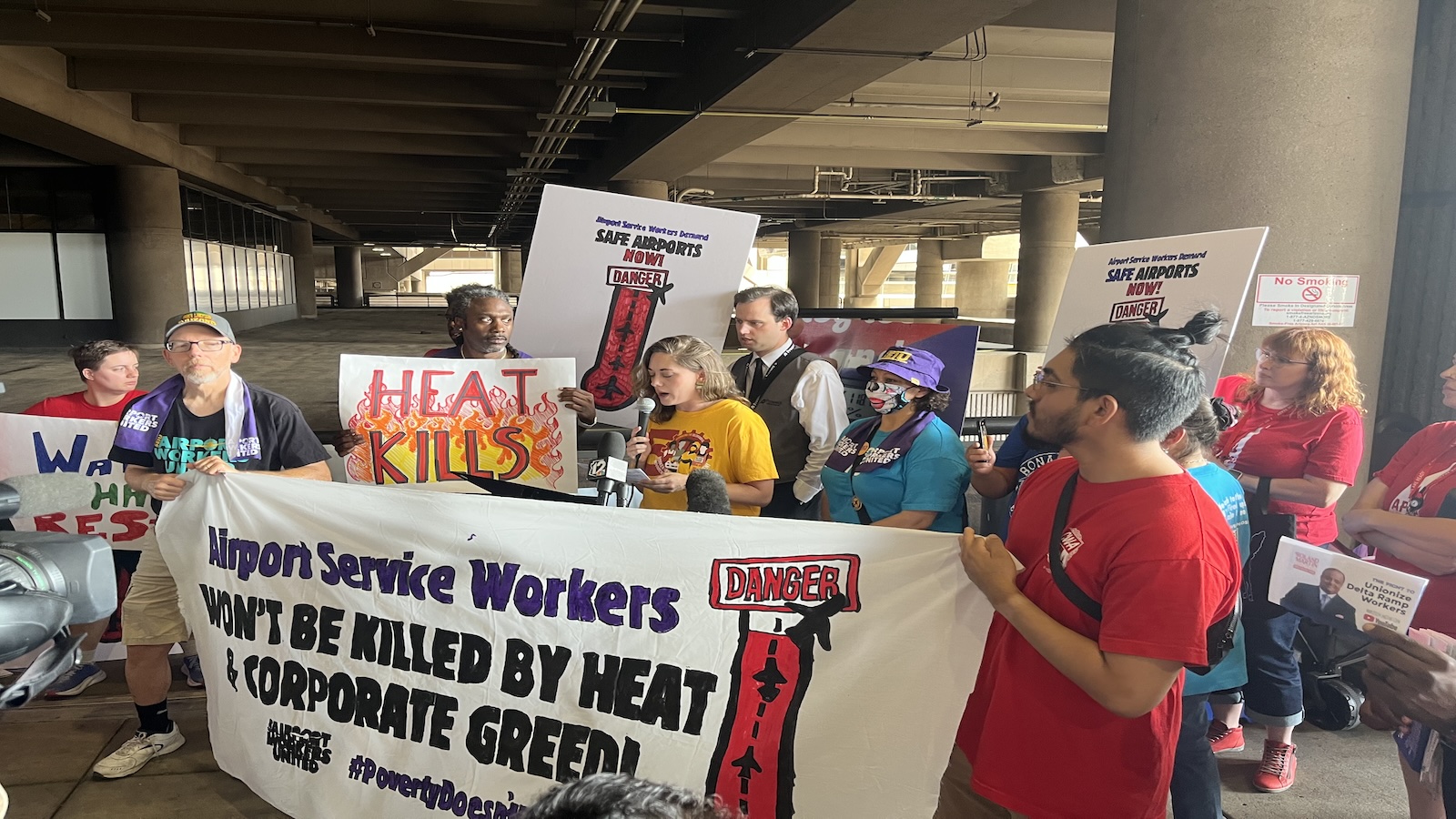

Workers rally across U.S. after spate of deaths due to heat wave

Jimenez, who advocates for immigrant farm workers with the grassroots organization Alianza Agrícola, said automation “could become a tactic, like a strategy for bosses, so people will be afraid and not demand their rights.” Ultimately, robots are “machines that don’t ask for anything,” he added. “We don’t want to be replaced by machines.”

Associated Press reporters Amy Taxin in Santa Ana, California, and Dorany Pineda in Los Angeles contributed to this report. Walling reported from Chicago and Horn-Muller reported from Homestead., Florida.